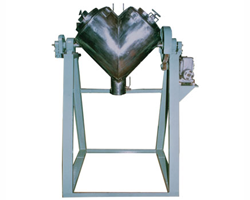

" V " Blender

Used for mixing of flow able powders. Capacity - (10 to 6000 liters).

Used for mixing of flow able powders. Capacity - (10 to 6000 liters).

TRAXIT "V" Blender - is an out growth of a simple cylinder which is split and rejoined to form a "V". As a result the product being processed undergoes divergent and convergent flow there by giving precision blending in short time. The top ends of the container are provided with closures on which are provided quick opening covers. The container along with all the appurtenances is supported by means of trunion shaft which is supported by two bearings. The product after processing can be discharged through a discharge nozzle which will be fitted with a butterfly valve or a slide valve. This discharge nozzle can also be used for feeding the material to be processed in case of larger blenders.

Advantages of "V" Blender to other conventional blenders:-

1. The product being processed is rotated close to the axis of rotation and hence the power required is low without affecting the mixing efficiency.

2. The unit has two large openings so the interior is readily accessible for cleaning.

3. As the mixing is by gravitational movement it can handle extremely delicate and also heavy and abrasive materials.

The "V" Blender can be used for dry blending or with added features for incorporating liquid ingredients into powders and even for effecting drying.

It finds extensive application in varied industries like - Pharmaceutical, Metal Powder, Chemical, Food, Plastic, Soap and Detergent, Agro chemical, Ceramic, Cosmetic, etc.

TRAXIT "V" Blenders can be made available form Laboratory models of 5 liters to Production models of 10, 000 Liters capacity.

Our Products

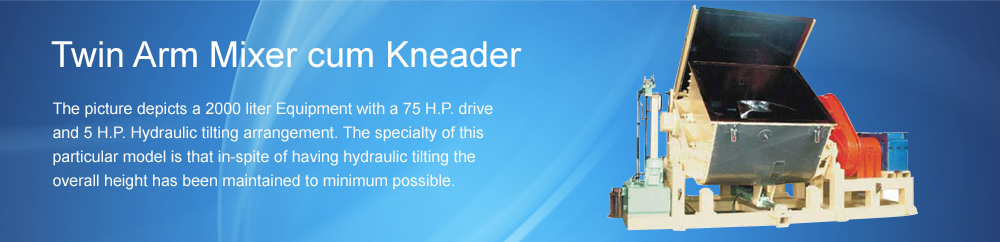

- Twin Arm Mixer cum Kneader

- Tailor Made Planetary Mixers

- Contra Mixer

- Rubber Cutter Dissolver

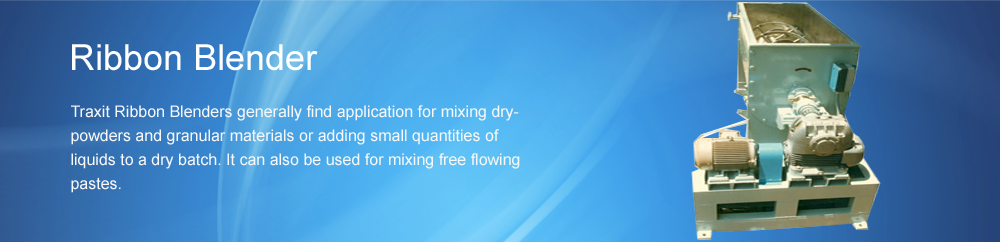

- Ribbon Blender

- Ploughshare Mixers

- "V" Blender

- Vertical Rotary Air Lock

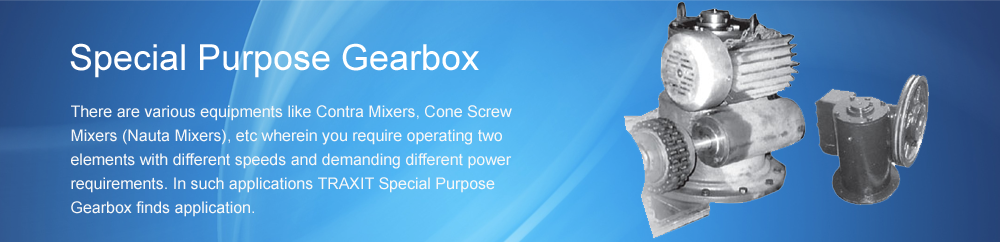

- Special Purpose Gearbox

- TEPL Lube Applicator

- Vertical Ribbon Blender

- Continuous Kneader

- Vacuum Double Planetary Mixer

- Schredder

- Disperser

- Cone Screw Mixer

- MFB Mixer